In today’s complex business environment, decision trees have become essential tools for optimizing operational strategies across quality control, inventory management, and product release workflows.

🌟 The Foundation of Strategic Decision-Making

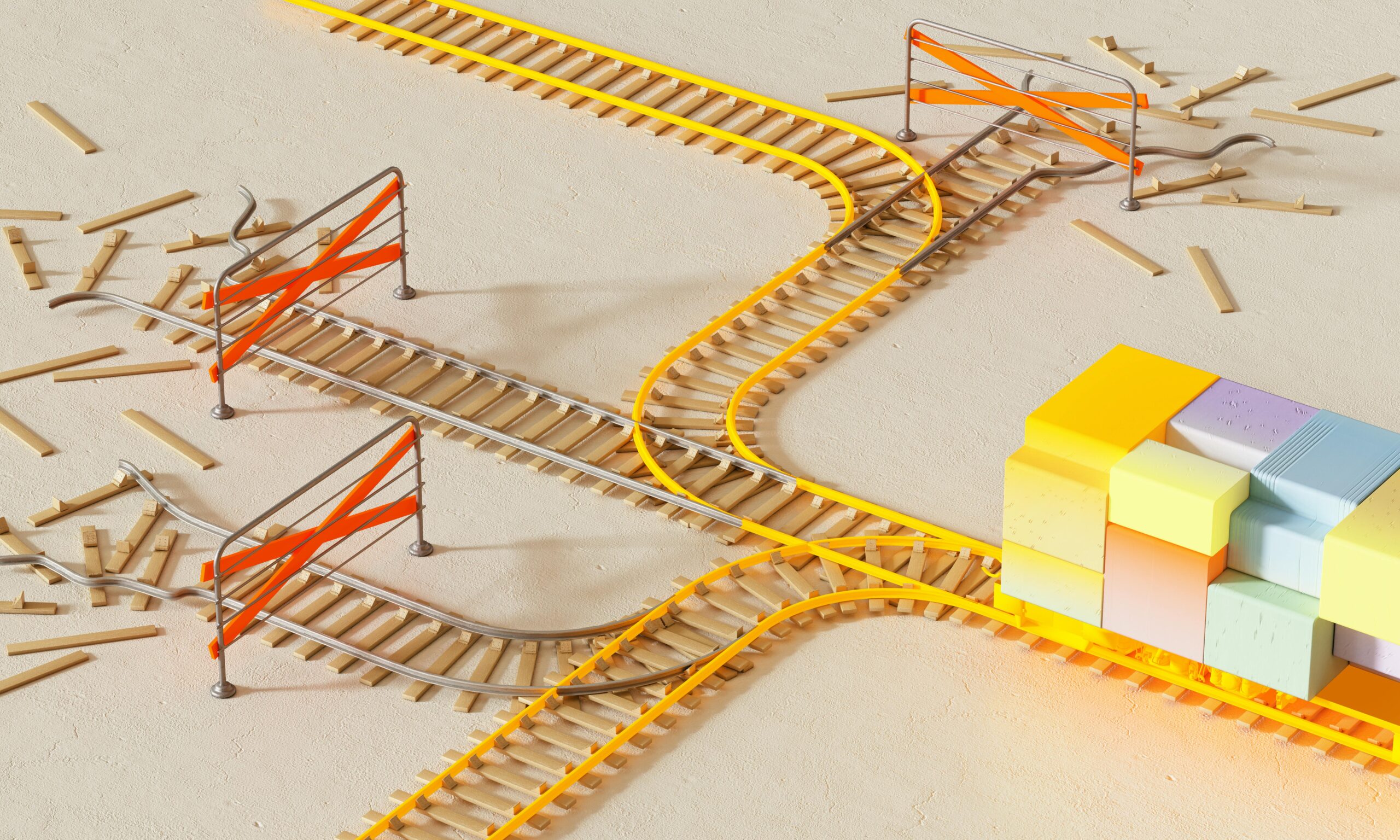

Decision trees represent one of the most powerful analytical frameworks available to modern organizations. These hierarchical structures enable teams to visualize complex decision pathways, systematically evaluate alternatives, and implement consistent processes across disposition, quarantine, and release operations. By mapping out every possible scenario and its corresponding action, businesses can dramatically reduce errors, improve compliance, and accelerate decision-making cycles.

The beauty of decision tree methodology lies in its versatility. Whether you’re managing pharmaceutical products, food safety protocols, manufacturing quality control, or digital asset management, the fundamental principles remain remarkably consistent. Each branch represents a decision point, each node captures a specific condition or criterion, and each leaf delivers a clear outcome or recommendation.

Understanding Disposition Strategies Through Decision Trees

Disposition decisions determine what happens to products, materials, or assets after inspection or evaluation. These critical choices directly impact profitability, regulatory compliance, and brand reputation. A well-structured decision tree for disposition strategies considers multiple variables simultaneously, including product condition, regulatory requirements, market demand, cost considerations, and risk factors.

Traditional disposition approaches often rely on individual judgment or inconsistent criteria, leading to variability in outcomes. Decision trees eliminate this inconsistency by establishing clear, documented pathways that every team member can follow. This standardization ensures that similar situations always receive similar treatment, which is particularly crucial in regulated industries where documentation and justification of decisions are mandatory.

Key Elements of Effective Disposition Decision Trees

When constructing decision trees for disposition strategies, several critical components must be incorporated. First, establish clear entry criteria that define when the decision tree should be activated. This might include triggering events such as failed quality tests, customer returns, expiration dates, or damage reports.

Next, identify all relevant decision factors that influence disposition outcomes. These typically include:

- Severity and type of defect or nonconformance

- Regulatory compliance status and requirements

- Economic value of the product or material

- Available corrective actions and their costs

- Risk to end users or customers

- Environmental and sustainability considerations

- Market conditions and alternative uses

Each decision node should pose a specific, measurable question with clearly defined response options. Avoid ambiguous criteria like “significant damage” in favor of quantifiable thresholds such as “damage affecting more than 15% of surface area” or “functionality reduced by more than 20%.”

🔍 Implementing Quarantine Protocols with Decision Tree Logic

Quarantine represents a critical holding state where products or materials await further evaluation or corrective action. Effective quarantine management prevents contaminated, defective, or suspect items from entering the supply chain while allowing for thorough investigation and appropriate disposition.

Decision trees excel at quarantine management by systematically addressing three fundamental questions: What should be quarantined? How should quarantined items be handled? When should items exit quarantine? Each question branches into multiple considerations that collectively ensure comprehensive protection without unnecessarily tying up valuable inventory.

Designing Quarantine Decision Pathways

The quarantine decision tree typically begins with detection or identification of a potential issue. This might originate from automated quality control systems, visual inspections, laboratory test results, customer complaints, or supplier notifications. The initial branch point evaluates whether the concern warrants immediate quarantine or can proceed through normal channels with enhanced monitoring.

For items entering quarantine, subsequent decision nodes address containment scope. Should only the specific batch be quarantined, or does the issue potentially affect multiple lots? Are similar products from the same supplier or manufacturing period also at risk? These branching decisions ensure that quarantine measures are appropriately scaled to the risk level without overreacting.

Once quarantined, the decision tree guides investigation protocols. Different types of issues require different analytical approaches. Physical defects might need dimensional analysis and stress testing, while contamination concerns demand microbiological or chemical analysis. The tree structure ensures that appropriate testing is always performed based on the specific nature of the concern.

Optimizing Release Strategies for Maximum Efficiency

Release decisions represent the final gateway between production or storage and distribution or use. These determinations carry significant weight because releasing nonconforming products can result in recalls, regulatory action, customer harm, and brand damage, while unnecessarily holding conforming products creates cash flow problems and supply chain disruptions.

Decision trees bring rigor and consistency to release strategies by establishing clear acceptance criteria and verification requirements. Rather than relying on individual judgment or incomplete information, the structured approach ensures that every relevant factor receives appropriate consideration before release authorization.

Building Comprehensive Release Decision Frameworks

Effective release decision trees incorporate multiple verification layers. The first layer typically addresses whether all required testing and inspection activities have been completed. Incomplete evaluation automatically routes to a “hold pending completion” outcome, preventing premature release based on partial information.

The second layer evaluates whether results meet established acceptance criteria. This involves comparing test results, measurements, and observations against specifications, regulatory requirements, and quality standards. The decision tree must account for both pass/fail criteria and marginal cases that may require additional evaluation or risk assessment.

Conditional release represents a sophisticated branch in release decision trees. When products meet most but not all standard criteria, or when minor deviations exist that don’t impact fitness for use, conditional release pathways allow for controlled distribution with appropriate restrictions, labeling, or customer notification. The decision tree ensures that such decisions follow consistent logic and include proper documentation.

📊 Integrating Data and Analytics into Decision Tree Structures

Modern decision trees increasingly incorporate quantitative data and predictive analytics to enhance decision quality. Rather than relying solely on predetermined thresholds, advanced implementations leverage historical data, statistical models, and machine learning algorithms to continuously refine decision criteria and outcomes.

For disposition decisions, analytics might reveal that certain types of defects actually have minimal impact on customer satisfaction or product performance, suggesting opportunities to reclassify some items from reject to accept or downgrade categories. Conversely, data might identify subtle indicators that correlate with higher failure rates, prompting more stringent quarantine or rejection criteria.

Creating Data-Driven Decision Nodes

Incorporating analytics into decision trees requires careful attention to data quality and relevance. Each data-driven decision node should specify the data sources, calculation methods, and interpretation guidelines. For example, a node evaluating batch release might incorporate real-time process data, environmental conditions during manufacturing, supplier quality metrics, and historical performance of similar batches.

Threshold values within the decision tree should be periodically reviewed and adjusted based on accumulated evidence. What constitutes acceptable variation may change as processes improve, customer expectations evolve, or regulatory requirements are updated. The decision tree structure should include review triggers and version control to ensure that criteria remain current and appropriate.

🚀 Practical Implementation Strategies for Decision Trees

Translating decision tree concepts into operational reality requires thoughtful planning and stakeholder engagement. The most elegant theoretical framework will fail if users find it impractical, confusing, or disconnected from daily workflows. Successful implementation balances comprehensiveness with usability, ensuring that decision trees serve as helpful tools rather than bureaucratic obstacles.

Begin implementation with collaborative development sessions involving representatives from all affected functions. Quality assurance, production, laboratory, warehouse, regulatory affairs, and management perspectives all contribute valuable insights that strengthen the final decision tree structure. This collaborative approach also builds ownership and commitment to using the new system.

Training and Adoption Best Practices

Even the best-designed decision tree requires effective training to ensure consistent application. Training should go beyond simply explaining the tree structure to include the rationale behind key decision points, examples of how to handle ambiguous situations, and practice scenarios that allow users to develop confidence.

Consider creating quick reference guides that distill complex decision trees into simplified flowcharts for routine situations, while maintaining access to the complete detailed version for unusual cases. Digital tools and mobile applications can further enhance usability by presenting relevant decision tree branches based on user inputs and automatically documenting the decision pathway followed.

Measuring Success and Continuous Improvement

Implementing decision trees for disposition, quarantine, and release strategies represents a starting point rather than a destination. Ongoing monitoring of key performance indicators reveals whether the decision framework delivers intended benefits and identifies opportunities for refinement.

Track metrics such as decision consistency across users and situations, time required to reach disposition decisions, error rates in release decisions, inventory carrying costs for quarantined materials, and regulatory compliance performance. Comparing these metrics before and after decision tree implementation quantifies the value delivered and justifies continued investment in the approach.

Adapting to Changing Requirements and Conditions

Business environments constantly evolve, with new products, processes, regulations, and customer expectations requiring corresponding adjustments to decision frameworks. Establish a governance process for reviewing and updating decision trees at regular intervals and in response to trigger events such as regulatory changes, quality incidents, or process modifications.

Document the reasoning behind decision tree changes to maintain institutional knowledge and support future refinements. This documentation also proves valuable during regulatory audits or quality system reviews by demonstrating that decision criteria receive appropriate oversight and continuous improvement attention.

🎯 Advanced Considerations for Complex Operations

Organizations with diverse product portfolios, multiple facilities, or international operations face additional complexity in decision tree implementation. A single universal decision tree may prove too generic to address product-specific nuances, while completely separate trees for each product create maintenance burdens and consistency challenges.

The solution often involves modular decision tree architectures with core common decision logic supplemented by product-specific or facility-specific branches. This approach captures universal principles such as regulatory compliance requirements and risk assessment methodology while accommodating unique characteristics of different products or locations.

Technology Enablement and Automation

Modern quality management systems and enterprise resource planning platforms increasingly include decision tree functionality that can automate routine decisions while flagging complex situations for human review. Automation accelerates decision-making, eliminates transcription errors, and creates comprehensive audit trails that document exactly how each disposition, quarantine, or release decision was reached.

When implementing technological solutions, ensure that the system maintains flexibility to handle exceptions and unusual situations. Rigid automation that cannot accommodate legitimate variations creates workarounds that undermine the entire decision framework. The goal should be intelligent assistance that guides users through the decision process while preserving human judgment for ambiguous cases.

Regulatory Compliance and Documentation Excellence

In regulated industries such as pharmaceuticals, medical devices, food production, and aerospace, decision trees serve double duty as both operational tools and compliance documentation. Regulatory agencies increasingly expect to see documented decision-making processes that ensure consistent application of quality standards and traceability of disposition decisions.

Well-constructed decision trees directly support regulatory compliance by demonstrating that organizations have systematic processes for handling nonconforming materials, that decisions follow predefined criteria rather than arbitrary judgment, and that appropriate documentation accompanies each decision. During inspections or audits, decision trees provide clear evidence of quality system robustness and maturity.

🌐 Building a Culture of Systematic Decision-Making

Beyond the technical aspects of decision tree construction and implementation, success ultimately depends on organizational culture. Teams must embrace systematic decision-making as superior to ad hoc approaches, even when the structured process initially feels slower or more cumbersome than simply making intuitive judgments.

Leadership plays a crucial role in establishing this culture by consistently referring to and following decision tree frameworks, recognizing employees who identify opportunities to improve decision structures, and resisting pressure to override systematic processes based on convenience or expediency. Over time, as the benefits of consistent decision-making become evident through improved quality metrics and reduced variability, the approach becomes embedded in organizational DNA.

The Path Forward: Strategic Advantages of Decision Tree Mastery

Organizations that master decision tree methodology for disposition, quarantine, and release strategies gain significant competitive advantages. They achieve higher quality consistency, faster decision cycles, better regulatory compliance, reduced inventory carrying costs, and stronger organizational knowledge that survives personnel changes.

These benefits compound over time as decision trees are refined based on experience, as employees develop deeper understanding of the systematic approach, and as technology enables increasingly sophisticated decision support. What begins as a simple flowchart evolves into a comprehensive decision framework that captures organizational expertise and continuously improves operational performance.

The investment required to develop and implement effective decision trees pays dividends through reduced quality costs, minimized regulatory risk, improved customer satisfaction, and enhanced operational efficiency. In an era where quality expectations continue rising while margins face pressure, systematic approaches to critical decisions separate industry leaders from followers. By embracing decision tree methodology and continuously refining your approach, your organization positions itself for sustained success in managing the complex challenges of modern quality and inventory management.

Toni Santos is a compliance specialist and technical systems consultant specializing in the validation of cold-chain monitoring systems, calibration certification frameworks, and the root-cause analysis of temperature-sensitive logistics. Through a data-driven and quality-focused lens, Toni investigates how organizations can encode reliability, traceability, and regulatory alignment into their cold-chain infrastructure — across industries, protocols, and critical environments. His work is grounded in a fascination with systems not only as operational tools, but as carriers of compliance integrity. From ISO/IEC 17025 calibration frameworks to temperature excursion protocols and validated sensor networks, Toni uncovers the technical and procedural tools through which organizations preserve their relationship with cold-chain quality assurance. With a background in metrology standards and cold-chain compliance history, Toni blends technical analysis with regulatory research to reveal how monitoring systems are used to shape accountability, transmit validation, and encode certification evidence. As the creative mind behind blog.helvory.com, Toni curates illustrated validation guides, incident response studies, and compliance interpretations that revive the deep operational ties between hardware, protocols, and traceability science. His work is a tribute to: The certified precision of Calibration and ISO/IEC 17025 Systems The documented rigor of Cold-Chain Compliance and SOP Frameworks The investigative depth of Incident Response and Root-Cause The technical validation of Monitoring Hardware and Sensor Networks Whether you're a quality manager, compliance auditor, or curious steward of validated cold-chain operations, Toni invites you to explore the hidden standards of monitoring excellence — one sensor, one protocol, one certification at a time.